WASTEWATER TREATMENT PROCESS DESIGN CALCULATOR | NO 1

Biological process design (Biokinetics approach) for

Modified activated sludge process – Extended aeration for BOD removal only

Objectives:

-

Calculate size of aeration tank

-

Calculate sludge production

-

Calculate F/M ratio

-

Calculate aeration blower size

Theoretical basis:

Design Philosophy

The design is based on the substrate utilization rate following microbial kinetics (Michaelis – Menten Enzyme Substrate reaction). The approach used in the design was as follows:

- Selection of target SRT

- Solving the solids generation based on the above SRT, minimum wastewater temperature & at a fixed MLSS concentration

- The volume of the aeration reactor is calculated after estimation of solids generation at a fixed MLSS

- After the volume of aeration reactor is determined, Oxygen requirement is calculated based on the standard equation considering the tender specifications

- For sizing denitrification reactor, and for arriving at most optimal reactor sizing equations governing denitrification kinetics are used

- After sixing the denitrification reactor the anaerobic tank is sized by choosing a fixed reactor volume from 0.5-1 hr HRT

- Solid separation is then design based on the maximum of SOR, SOR at peak flow, SLR and SLR of peak flow and also considering all other specifications as per tender requirements

All design specification used were as per tender document and CPHEEO. In case, if neither CPHEEO nor tender stipulated a specification, standard texts like Metcalf & Eddy, Syed R. Qasim, WEF MOP were used as reference.

Design parameters

| Biokinetic parameter at 20 C | |||||

|---|---|---|---|---|---|

| Description | Parameters | Units | COD oxidation | NH4 oxidation | NO2 oxidation |

| Maximum Specific Growth rate | µ_max | g bsCOD/g VSS.d | 6.00 | 0.9 | 1 |

| Half Velocity Constant | K_s /K_nh4/K_no2 | mg/L | 8 | 0.5 | 0.2 |

| Synthesis yield | Y | mg VSS/mg substrate | 0.45 | 0.15 | 0.05 |

| Specific Endogenous Decay Rate | b | g VSS/g VSS.d | 0.12 | 0.17 | 0.17 |

| Fraction of Biomass that remain as cell debris | f_d | unitless | 0.15 | 0.15 | 0.15 |

| Half Velocity Constant for Oxygen | K_o2 | mg/L | 0.2 | 0.5 | 0.9 |

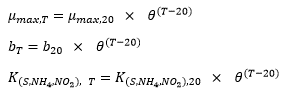

Temperature correction

| Temperature correction coefficients for biokinetic parameters | ||||

|---|---|---|---|---|

| Theta value | Units | COD oxidation | NH4 oxidation | NO2 oxidation |

| µ_max | unitless | 1.07 | 1.072 | 1.063 |

| b | unitless | 1.04 | 1.029 | 1.029 |

| K_s /K_nh4 /K_no2 | unitless | 1 | 1 | 1 |

Calculator

(Note – all Yellow are user defined value, all white are fixed values,

all green are calculated value, all orange is calculated not to be

shown)

Instructions

Enter values highlighted in the

Yellow

Green highlights

are the results

In case of

any invalid result of non-functioning of the calculator, please write

to us at urvpatel@swaenviro.com. We will try and help you with your

sizing and calculation

INPUT

| Parameter | Value | Unit | Remarks |

|---|---|---|---|

| Flowrate | MLD | ||

| Recirculated flow | % | Typical 3% | Range from 2-5% | May be higher based on wastewater | |

| Average flowrate | 0.01 | cum/s | |

| Enter Wastewater characteristics | |||

| Chemical Oxygen Demand, COD | Typically in sewage 250-450 mg/l | ||

| Biochemical Oxygen Demand, BOD | Typically in sewage 100-250 mg/l | ||

| Total Suspended Solids, TSS | Typically in sewage 250-350 mg/l | ||

| Voltalite Suspecded Solids, VSS | Typically in sewage 200-250 mg/l | ||

| gram COD per gram of VSS | Typically in sewage 0.125 | ||

| nbVSS | mg/l | Typically in sewage 10% of VSS | |

| Total Kjheldhal Nitrogen, TKN | mg/l | Typically in sewage 40-50 mg/l ; (Note for special case like TKN > 100 mg/l, contact our design engineering team for more accurate process deisgn) | |

| Ammonical Nitorgen, NH4-N | mg/l | Typically in sewage 40-50 mg/l (Note for special case like NH4-N > 100 mg/l, contact our design engineering team for more accurate process deisgn) | |

| Total Phosphorous, TP | mg/l | Typically in sewage 7.1 mg/l | |

| Design parameter | |||

| Select SRT | days | Changed based on the nutrient removal req; For BOD removal use 3-5 days & For BOD + Nitrification use 8-10 days | |

| Select X,TSS | mg/l | Change based on process ASP, Extended aeration, MBBR | |

| Temperature (Min) | deg C | As per site condition extreme | |

| Temperature (Max) | deg C | As per site condition extreme | |

| Aeration tank water depth | m | ||

| Treated Sewage Quality Summary | |||

| Biochemical Oxygen Demand, BOD | |||

| Chemical Oxygen Demand, COD | mg/l | ||

| Total Suspended Solids, TSS | mg/l | ||

| Total Nitorgen, TN | mg/l | Organic Nitrogen + Ammonical Nitrogem + Nitrates | |

| Total Phophorous, TP | mg/l | ||

| Ammonical Nitorgen, NH4-N | mg/l | ||

| PART A- Tank sizing or HRT , Sludge generation & F/M ratio | |||

| Outlet BOD theoritical | 0.284 | mg/l | Theoritical based on steady state condition and mass balance as per the SRT |

| Initial Guess for Nox | 32.00 | mg/l | Change value here by iteration till the calculations shows “CONVERGE” Start with intial guess of 80% of NH4-N |

| P_X,Bio,VSS | Biomass Production | ||

| Heterotrophic Biomass Solids | 88.96 | kg/day | First iteration |

| Non Biodegradable VSS in influent | 13.637 | kg/day | |

| Nitrifier Biomass solids | 2.02 | kg/day | |

| Nox (Based on P_x, Bio) | 17.4500 | (If negative then add the same amount in positive +10 mg/l in TKN input) | |

| Solids generation biological, P_X,Bio,VSS | 104.6 | kg/day | |

| Solids generation VSS, P_X,VSS | 129.6 | kg/day | |

| Solids generation TSS,P_X,TSS | 198.1 | kg/day | Sludge production on 100% dry basis |

| Net sludge geenration assuming 0.8% solids consistency | 24.76 | cum/day | @0.8% solids w/w OR 8000 mg/l TSS in Waste acitvated sludge wasted fro clarifier bottom |

| Net sludge geenration assuming 30% solids consistency after dewatering | 660.3 | kg/day | Wet sludge with 70% w/w moisture content |

| Mass of VSS in aeration tank | 907.3 | kg | |

| Mass of TSS in aeration tank | 1386.6 | kg | 787.991549737191 |

| Volume of aeration tank | 462 | cum | RESULT |

| Detention time (HRT) | 10.8 | hours | Based on Plant average flowrate + Recirculated |

| F/M (Food to Microorganisms ratio) | 0.23 | g BOD/g VSS * d | 0.15-0.25 as per CPHEEO MLVSS=0.8 MLSS |

| Effluent Nitrates (Assumed) | 5 | mg/l | |

| Oxygen credit (from denitrification) | 35.607 | kg/d | IMPORTANT NOTE: Applicable denidrification is provided in the form of anoxic tank, otherwise zero. For current use case the effluent nitrate level assumed as <5 mg/l | (For calculation of anoxic tank size refer Metclaf & Eddy) |

| PART B- Blower sizing | |||

| Oxygen demand | 263.54 | kg/day | |

| Oxygen credit from Denitrification | 30.27 | kg/day | 85% of the denitrification oxygen credit used |

| Oxygen demand | 9.72 | kg/hr | Considering denitrification |

| Calculating SOTR | Standard Oxygen Trasnfer Rate | ||

| Temperature of wastewater | deg-C | Based on Maximum wastewater temperate in the influent parameter section | |

| Actual Oxygen Trasfer Rate required, AOTR | 9.72 | kg/hr | |

| C, 20 deg cel | mg/l | From saturation table | |

| C, t deg cel | mg/l | From saturation table and maximum temp of wastewater and salinity | |

| C, tank | 2 | mg/l | Required minimum 2 mg/l |

| Alpha | Typical value : 0.65 | ||

| Beta | Typical value : 0.95 | ||

| F | Typical value : 0.9 | ||

| Mid depth correction factor | 0.25-0.4 | ||

| Depth of diffusers | 4.3 | ||

| Temp correction | 0.70 | ||

| Elevation of site | m | As per site elevation from sea level | |

| Std barometric pressure | 0.989 | ||

| Saturated DO due to pressure from water column | 10.60 | ||

| Standard Oxygen Trasnfer Efficiency | 40.28 | kg/hr | |

| Trasfer efficiency | fraction | 7.5% per meter of water depth as per vendor | |

| Weight of Oxygen per cum of air | kg O2/cum-air | ||

| Efficiency | |||

| Normal Temperature | 20 | ||

| Temperature of Air | 45 | ||

| Air Flowrate required in terms of NTP | 514.0 | Ncum/hr | Normalized @20 deg C |

| Total head loss in aeration | |||

| Total head loss in piping | 100.0 | mm | Typical 100 mm |

| Total head loss in in Elbow, Valves, Tee & Meteres | 50.0 | mm | Typical 100 mm |

| Total head loss in blower assembly | 100.0 | mm | Typical 100 mm |

| Head loss in fine bubble diffuser | 200.0 | mm | Typical 200 mm |

| Submergence head | 3800.0 | mm | 200 mm diffuser height |

| Head loss due to clogging | 212.5 | mm | 5 % of a+b+c+d |

| Total head loss across the pneumatic system | 4462.5 | mm | Desired blower pressure head required |

| Provide | 4.5 | mm WC | |

| SELECT BLOWER WITH | |||

| Air Flowrate required | 514.0 | Ncum/hr | Discharge side capacity @ NTP |

| Head | 4.47 | m | Submergence + Head loss in air piping |

| Summary of result | |||

| Volume of aeration tank | 462 | cum | |

| Hydraulic retention time | 11 | hr | |

| Sludge Generation | 24.76 | cum/day | |

| F/M ratio | 0.23 | g BOD/g VSS * d | |

| Hydraulic retention time | 10.8 | hours | |

| Blower capacity | 514.0 | Ncum/hr | |

| Blower head | 0.45 | kg/cm2 | |