Detailed design and engineering of STP, WTP & ETP

Our approach for process and hydraulic design & engineering not only integrate the client requirement for the treatment objectives but also the site conditions, such that not only the capital cost but the operations cost is also economized. Our deliverables include but not limited to following:

- Process flow diagram

- Process design calculations

- Hydraulic profile calculations

- Hydraulic flow diagram

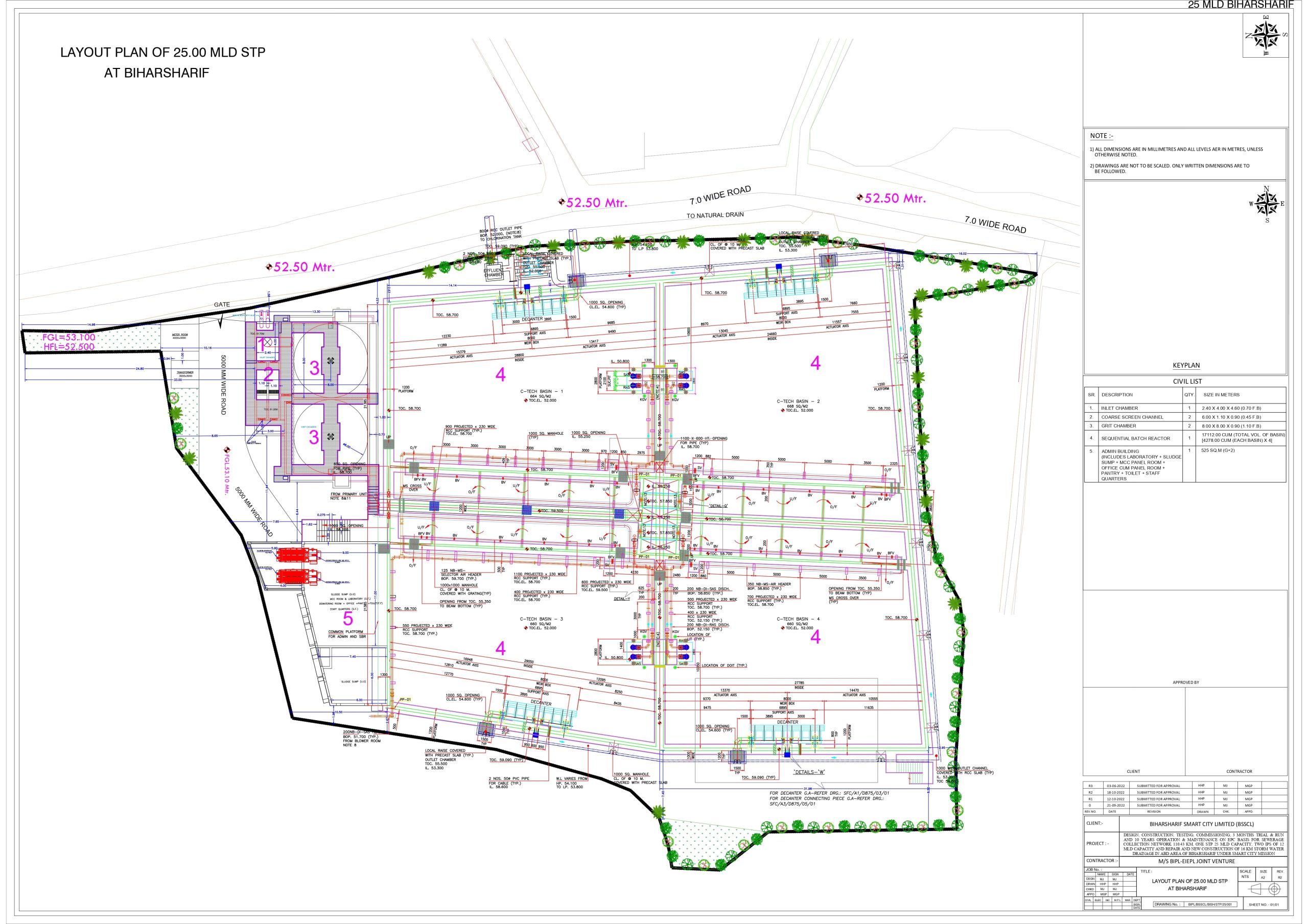

- Plant layout

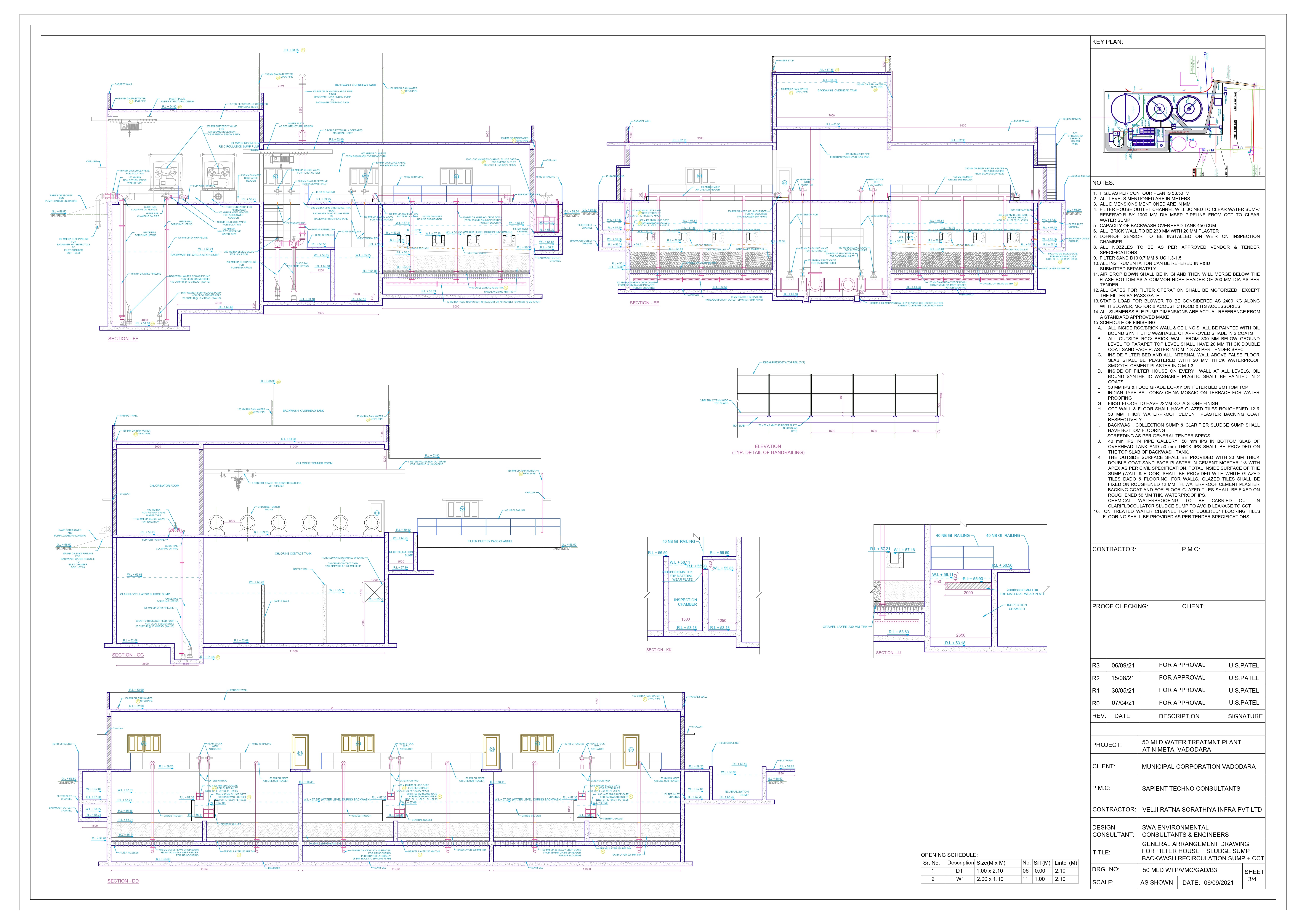

- General arrangement drawings (GAD)

- Structural design & drawings

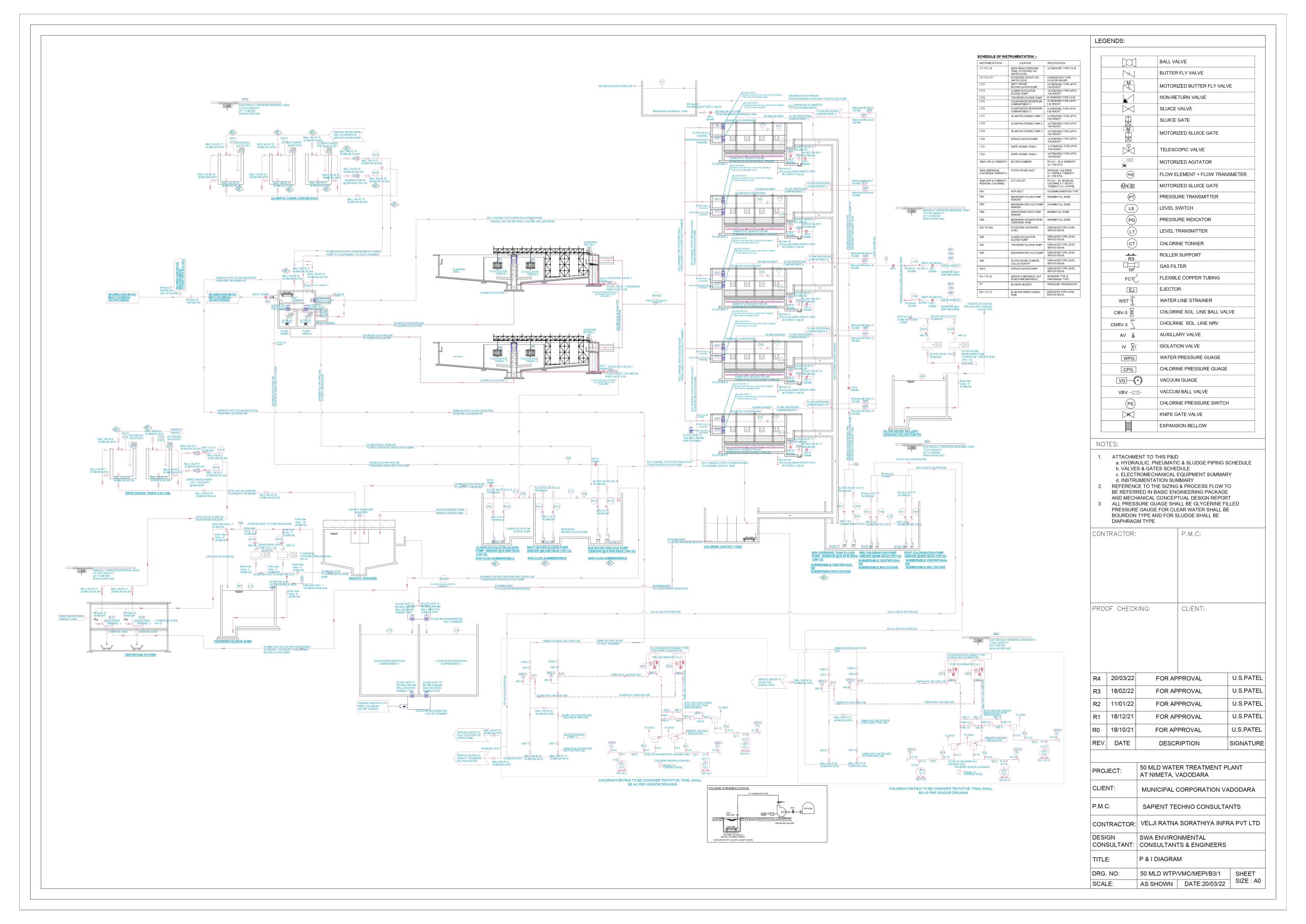

- Electromechanical design & drawings – Piping & Instrumentation Diagram

- Valve & Piping Schedule

- Mechanical component schedule

- Conceptual design report

- Electrical design & drawings

- Load list

- Transformer sizing

- Capacitor sizing

- Single line diagram

- Electrical switchyard general arrangement drawing

- Power & instrumentation cable sizing

- Cable tray layout

- Earthing design and drawing

- Lighting design & drawing

- Control Philosophy & Instrumentation Design for PLC & SCADA programming

- Instrumentation schedule

- As built drawings

- Plant piping isometrics

Typical deliverables & step by step procedure for WTP & STP design

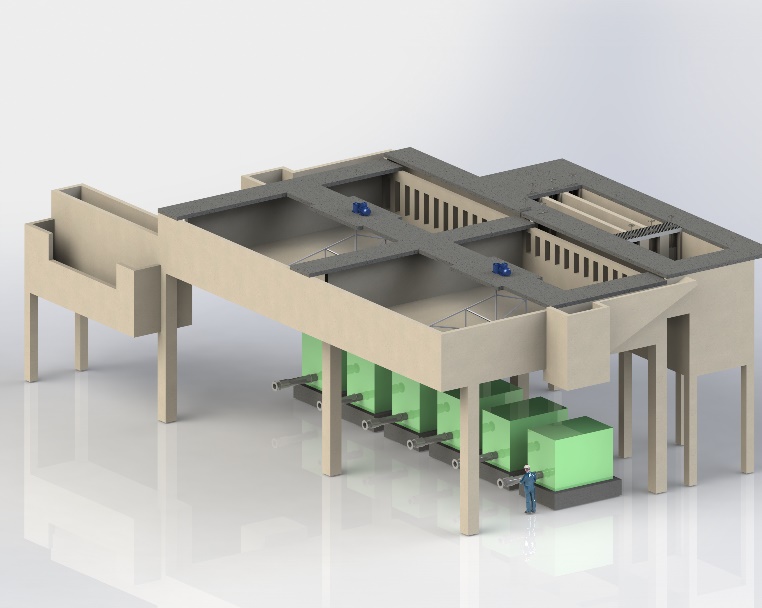

Project: 50 MLD Water Treatment Plant

Project: 25 MLD STP

Project: 50 MLD WTP

Project: 10 MLD Common Effluent Treatment Plant (CETP)

Project: 50 MLD WTP Filter House Section Drawing

We provide detailed design and engineering for following type of water and wastewater infrastructure:

- Water treatment plant (WTP)

- Sewage treatment plant (STP) based on following technologies

- Extended aeration

- Moving bed bioreactor (MBBR)

- Sequencing batch reactor (SBR)

- Membrane bio reactor (MBR)

- Effluent treatment plant (ETP)

- Upflow Anaerobic Sludge Blanket Reactor

- Extended aeration with tertiary treatment

- Zero liquid discharge plant based on RO + Multi Effect Evaporator

- Chemical coagulation based primary ETP

- Intake well for drinking water lifting from rivers, canals or reservoirs

PROJECT SHOWCASE

Some unique projects where we have applied iconoclastic solutions to solve problems like space constraints and reducing power consumption

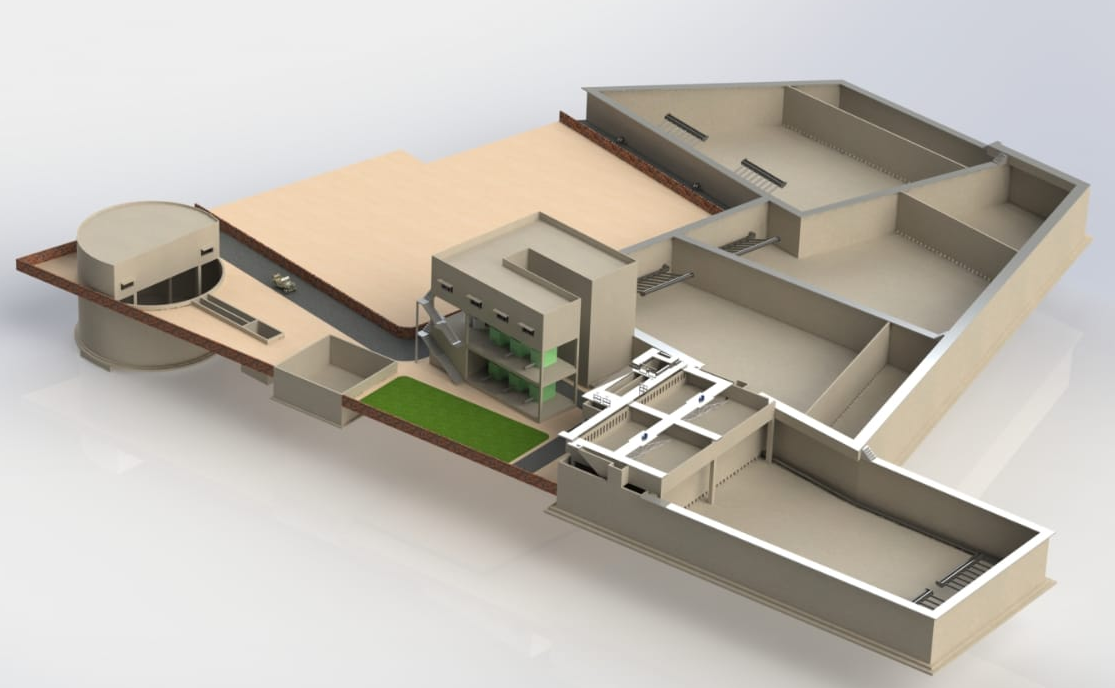

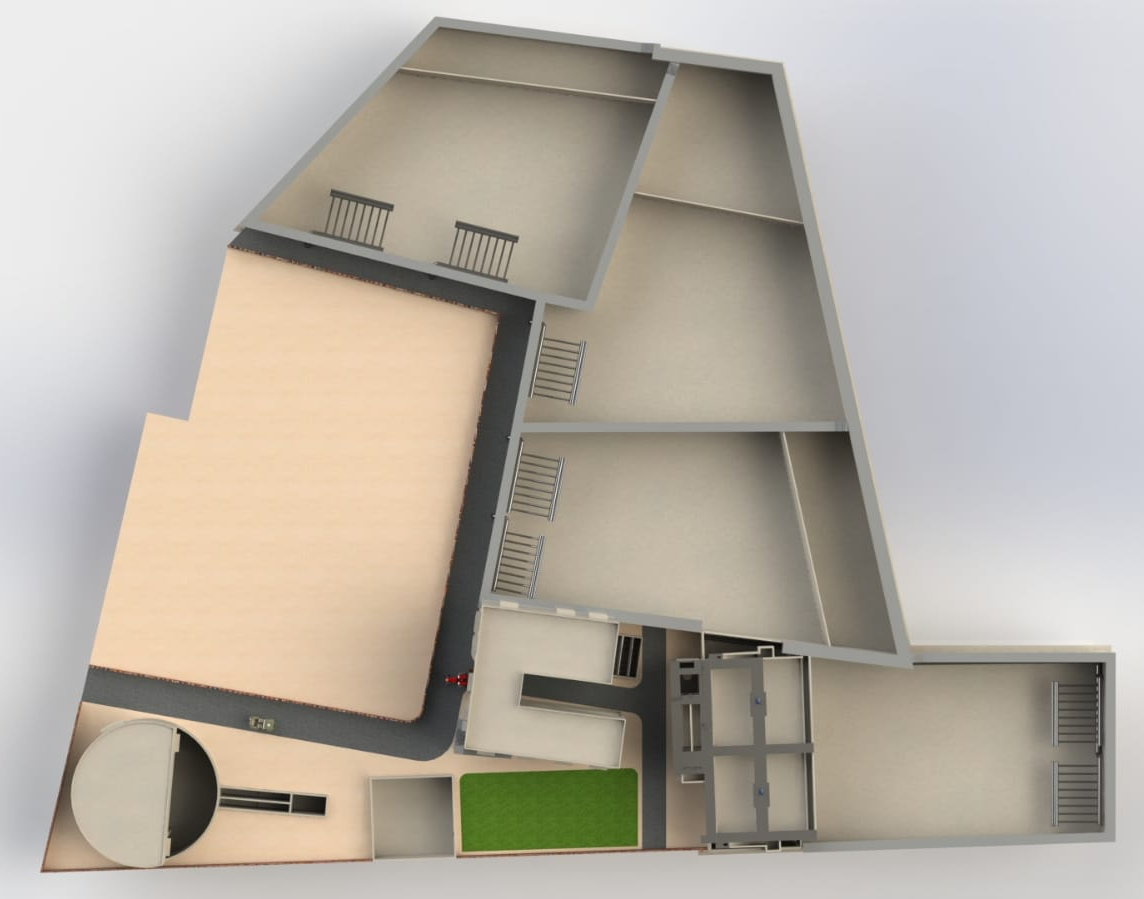

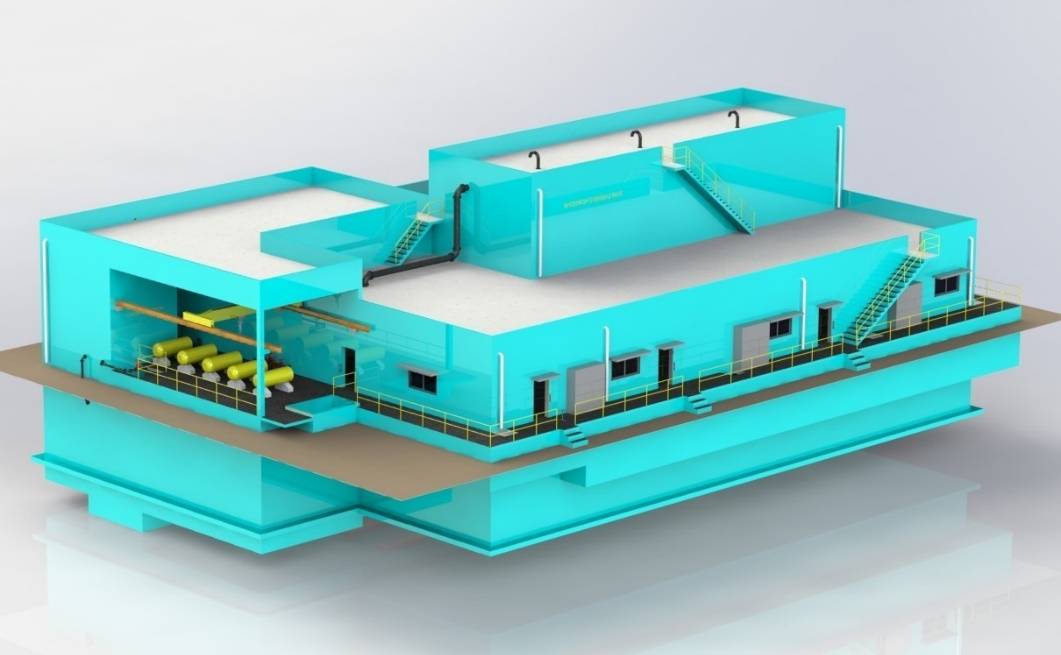

50 MLD STP based on SBR with pumping station accommodated in 7000 sqm plot, without multi stacking of unit (To know more Click here)

The unique feature and challenge were to accommodate all the units so that the power consumption and the construction economy without compromising the functionality of the plant during the O&M period

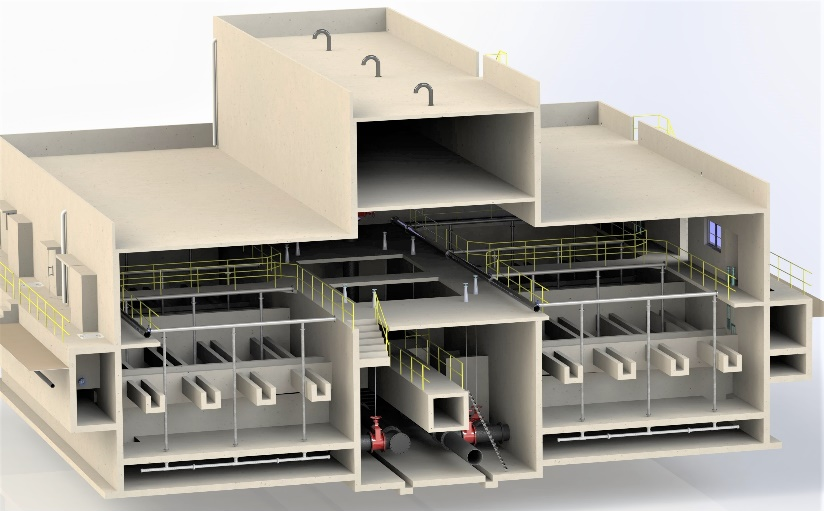

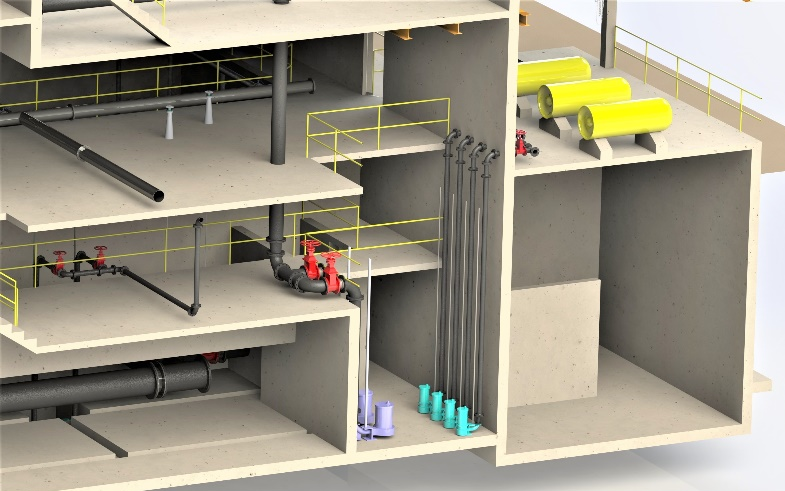

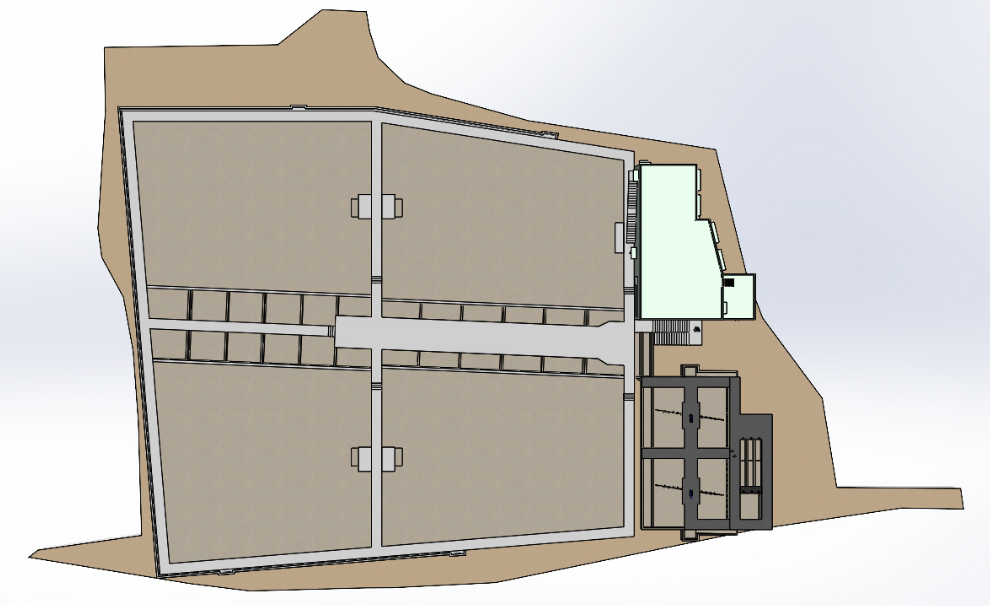

50 MLD WTP based on rapid sand filtration with gravity feed from reservoir, with sand filter at G minus 2 level (To know more Click here)

The unique feature and challenge were to accommodate backwash recirculation sump, chlorine contact tank and sludge sump combined in filter house and stacking of blower room above the backwash recirculation sump.

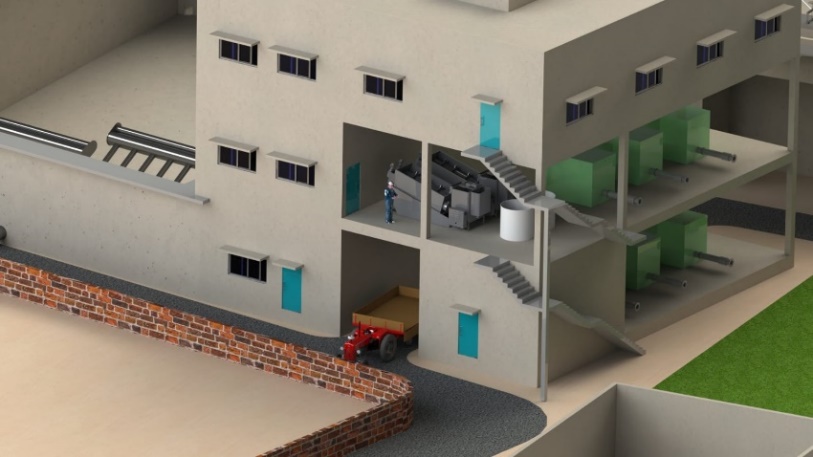

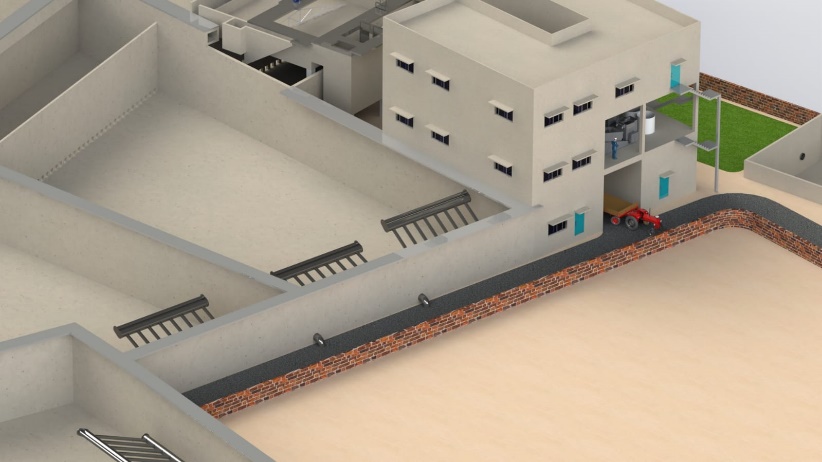

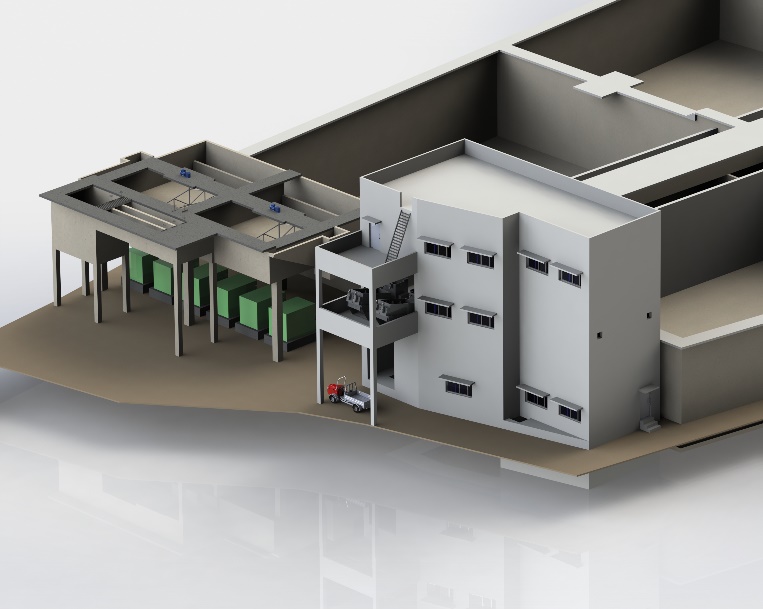

25 MLD STP based on SBR with pumping station accommodated in 4450 sqm (To know more Click here)

The unique feature and challenge was to accommodate all the units so that the power consumption and the construction economy without compromising the functionality of the plant during the O&M period. Blower room installed below the primary treatment unit and sludge sump below the administrative building and dewatering building complex was provided as a porch area to administrative building to enable free access around the plant.

Select Clients For Our Detailed Design & Engineering Services