(Author– Urv Patel)

It has been observed that many a times when the question of adequacy is asked, the most important question is to answer how exactly an auditor can determine the adequacy of a environmental management system. In this article, we will explore the various methodology for ascertaining the adequacy of wastewater EMS– i.e. Adequacy of ETP and STPs.

There are 2 major strategies through which the adequacy of a wastewater treatment plant can be determined:

- Water quality analysis of raw effluent & final treated water

- Design proof checking of each unit processes for adequate sizing as per the design parameter

Detailed description of strategies

1. Water quality analysis of raw effluent & final treated water

This method simply relies on the treated effluent and raw effluent characteristics, though which an auditor determined that the plant is performing as per the intended key performance indictors (KPIs). In simple words, if the treated effluent is under the permissible limit and the percentage reduction is as stipulated in the CCA (pollution control board consent), then the plant is assumed to be adequate.

Common laboratory analyses may include:

- pH, Conductivity: Tested using pH meters and conductivity meters.

- Biochemical Oxygen Demand (BOD): Measured using respirometry or manometric methods.

- Chemical Oxygen Demand (COD): Determined through closed reflux titrimetric or colorimetric methods.

- Total Suspended Solids (TSS): Analysed through filtration followed by drying in ovens.

- Ammonia Nitrogen (NH₃-N): Measured using Nessler’s reagent or ion-selective electrodes.

- Heavy Metals (e.g., Lead, Mercury): Detected using Atomic Absorption Spectroscopy (AAS) or Inductively Coupled Plasma Mass Spectrometry (ICP-MS).

Following are the advantages and drawbacks tied to this method

ADVANTAGES

- Simple and fast, the method gives a very quick idea regarding the performance of ETP & the STP

- Cheaper to determine as only analysis of wastewater is required for 2-3 samples

DRAWBACKS

- The performance is not representative of nameplate capacity, as the raw effluent flow and characteristics may be lower than the full flow capacity

- It is highly sensitive method when the sample size is very less, only 1–2-day sampling may not be representative of the consistency of operations around the year

- Only useful for a prima facie assessment of the ETP-STP performance, and cannot be used to certify the adequacy of the ETP or STP

2. Design proof checking of each unit processes for adequate sizing as per the design parameters

This method, is a much more systematic approach towards the performance appraisal of a wastewater treatment plant (WWTP), in which each unit operations and processes like equalization, aeration tank, anaerobic digester, secondary clarifier, tertiary treatment and others are proof checked for size. For example, the size of aeration tank can be checked by the biokinetics based approach or empirical approach by plugging in the full nameplate flow capacity and maximum effluent loading (COD/BOD/Ammonia etc.) in the textbook equations.

Key Design Checks:

- Aeration Tank Oxygen Demand: Verified using oxygen transfer efficiency (OTE) and specific oxygen uptake rate (SOUR).

- Clarifier Surface Overflow Rate (SOR) & Solids Loading Rate (SLR): Critical parameters to calculate the hydraulic capacity.

- Sludge Retention Time (SRT): Essential for biological treatment unit sizing.

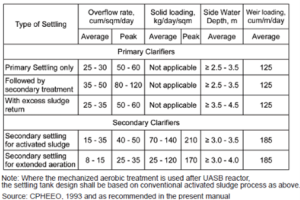

An illustration to check for secondary clarifier sizing:

1. Calculate the surface overflow rate & solids loading rate of the clarifier at average and peak, and take maximum of the 4 as design parameter

2. As per the selected SOR/SLR calculate the diameter or surface area of clarifier required

3. If the available is more than required then the size is adequate

Design parameter for secondary clarifier for activated sludge process (Source: CPHEEO)

Similarly, aeration tank, sand filter, activated carbon can be calculated based on standard spreadsheet calculators. A good resource, we have developed can be accessed online free of cost on following link:

https://swaenviro.com/calculate-aeration-tank-size-asp/.

ADVANTAGES

- More reliable check for the sizing as it is based on the worst-case scenario

- The method provides a good understanding whether the performance of the ETP or STP will be consistent or otherwise across the year

- Best possible fundamental assessment of the adequacy compared to just treated effluent analysis

- The practical analysis of the inlet and outlet can be used to help verify the theoretical calculation

DRAWBACKS

- Requires an experienced engineering calculations along with worst case design parameters

- The theoretical analysis which provides the basis may be inaccurate as it does not encompass, all the practical variables like slowly biodegradable COD and inhibitory components like phenol and other solvents which directly affects the biological activity (For this a more detailed piloting is required for the in-depth assessment and adequacy)

- Although, due to the ceremonial nature of environmental audit and adequacy certification for effluent treatment, it has become a norm to issue a certificate without proper assessment of the sizing based on design parameters and actual flow conditions or nameplate capacity

In conclusion, it is strongly advised to all the environmental auditors to use a more scientific and representative approach rather than just an observation of performance based on 1-2 effluent samples.

Good resources available for the calculations:

- Wastewater Engineering: Treatment and Resource Recovery, Metcalf & Eddy Ed-5

- CPHEEO manual for wastewater treatment

- https://swaenviro.com/calculators